CIRC

CIRC series

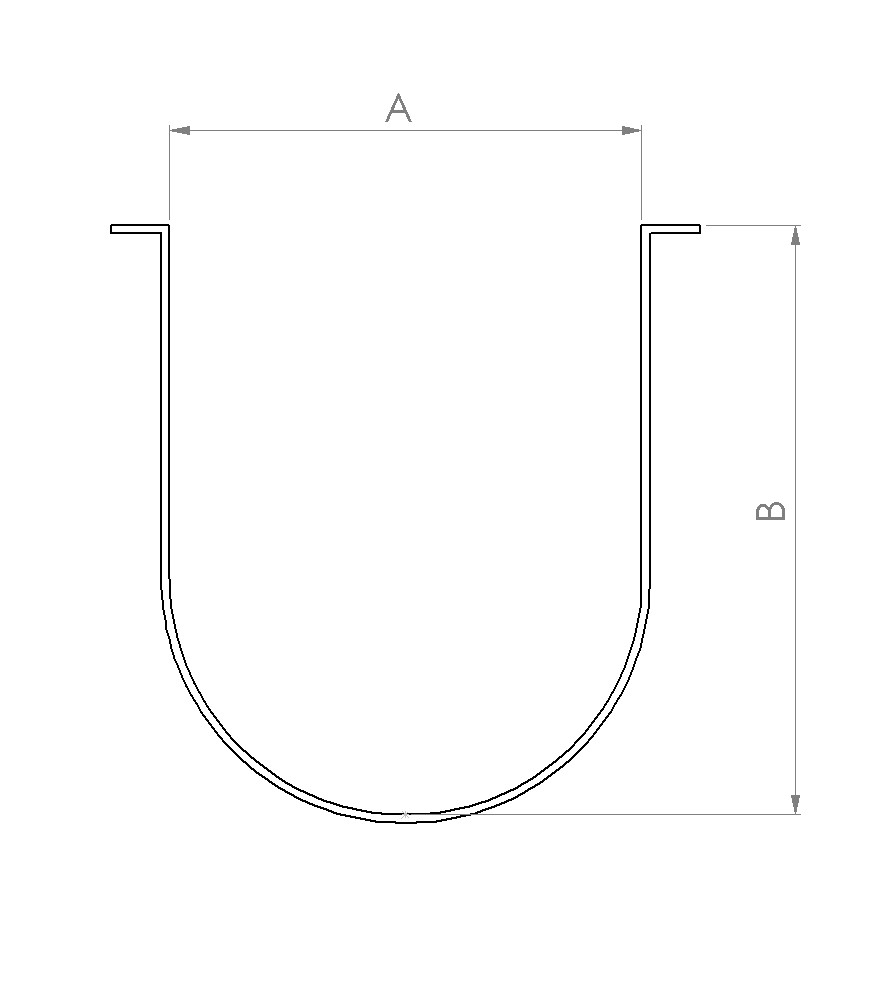

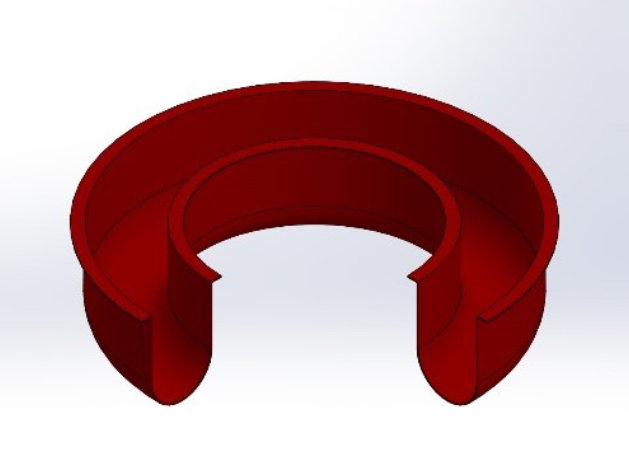

Our CIRC series circular vibrators are a simple, low-cost versatile solution for various vibratory finishing tasks in the bulk material process. These machines are suitable for small to medium-sized workpieces. The work bowl with a semi-annular, flat bottom ensures homogeneous distribution of workpieces and abrasives. The workpieces are removed manually. The work bowl is made of sheet steel with polyurethane lining. The vibration motors are designed for high centrifugal forces and are equipped with relubricatable bearings. The machine intensity can be flexibly adjusted by controlling the eccentric masses. The machines are individually equipped with customized metering and control technology.

Frame sizes

-

Gross volume:

100 - 1.100 litres

-

Usable volume:

70 - 860 litres

-

Drive capacities:

0,75 – 5,5 KW*

-

Speed:

1.500 R/min

-

Connector:

400 V / 50 Hz; CEE-Connector*

-

* Depending on the size of the machine and customer application.

Equipment

-

PU-lining

Control types

-

- Control with pushbutton and digital timer as well as operating hours counter

-

- Control with touch panel and MINI PLC

-

- PLC control Siemens S7 - customer-specific

Container cross-sections

Options

-

Conversion kit for continuous operation

-

Dosing unit for feeding water and compound

-

Magnetic separator

-

Process water recovery

-

Sound insulation cover (manual / pneumatic)

-

Reversal of direction of rotation

-

Speed control vibration motor

-

Chamber partition stationary, travelling

CIRC SE

CIRC SE series

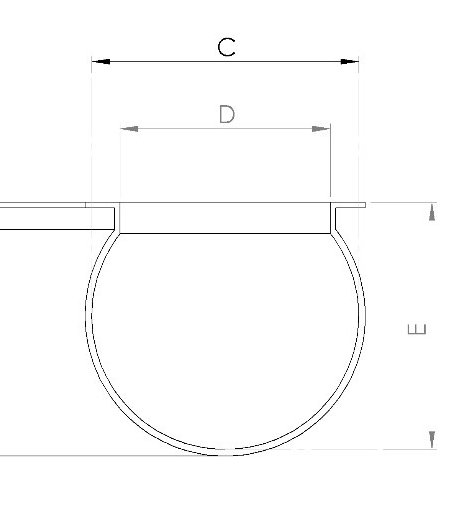

Our CIRC SE series circular vibrators are a simple, inexpensive versatile solution for various vibratory grinding tasks in the bulk material process. These machines are suitable for small to medium-sized workpieces. The spiral-shaped work bowl ensures optimum emptying and homogeneous distribution of workpieces and abrasives. The workpieces are removed by the operator or automatically by activating the pneumatic separating flap. The individually adapted sieve surface ensures optimum separation between workpieces and abrasives. The work bowl is made of sheet steel with polyurethane lining. The vibration motors are designed for high centrifugal forces and are equipped with relubricatable bearings. The machine intensity can be flexibly adjusted by regulating the eccentric masses.

Frame sizes

-

Gross volume:

100 - 1.100 litres

-

Usable volume:

70 - 860 litres

-

Drive capacities:

0,75 – 5,5 KW*

-

Speed:

1.500 R/min

-

Connector:

400 V / 50 Hz; CEE-Connector*

-

* Depending on the size of the machine and customer application.

Equipment

-

PU lining

-

Separation flap

Control types

-

- Control with pushbutton and digital timer as well as operating hours counter

-

- Control with touch panel and MINI PLC

-

- PLC control Siemens S7 - customer-specific

Container cross-sections

Options

-

Conversion kit for continuous operation

-

Dosing unit for feeding water and compound

-

Magnetic separator

-

Process water recovery

-

Sound insulation cover (manual / pneumatic)

-

Reversal of direction of rotation

-

Speed control vibration motor

-

Chamber partition stationary, travelling