MITRO

MITRO series

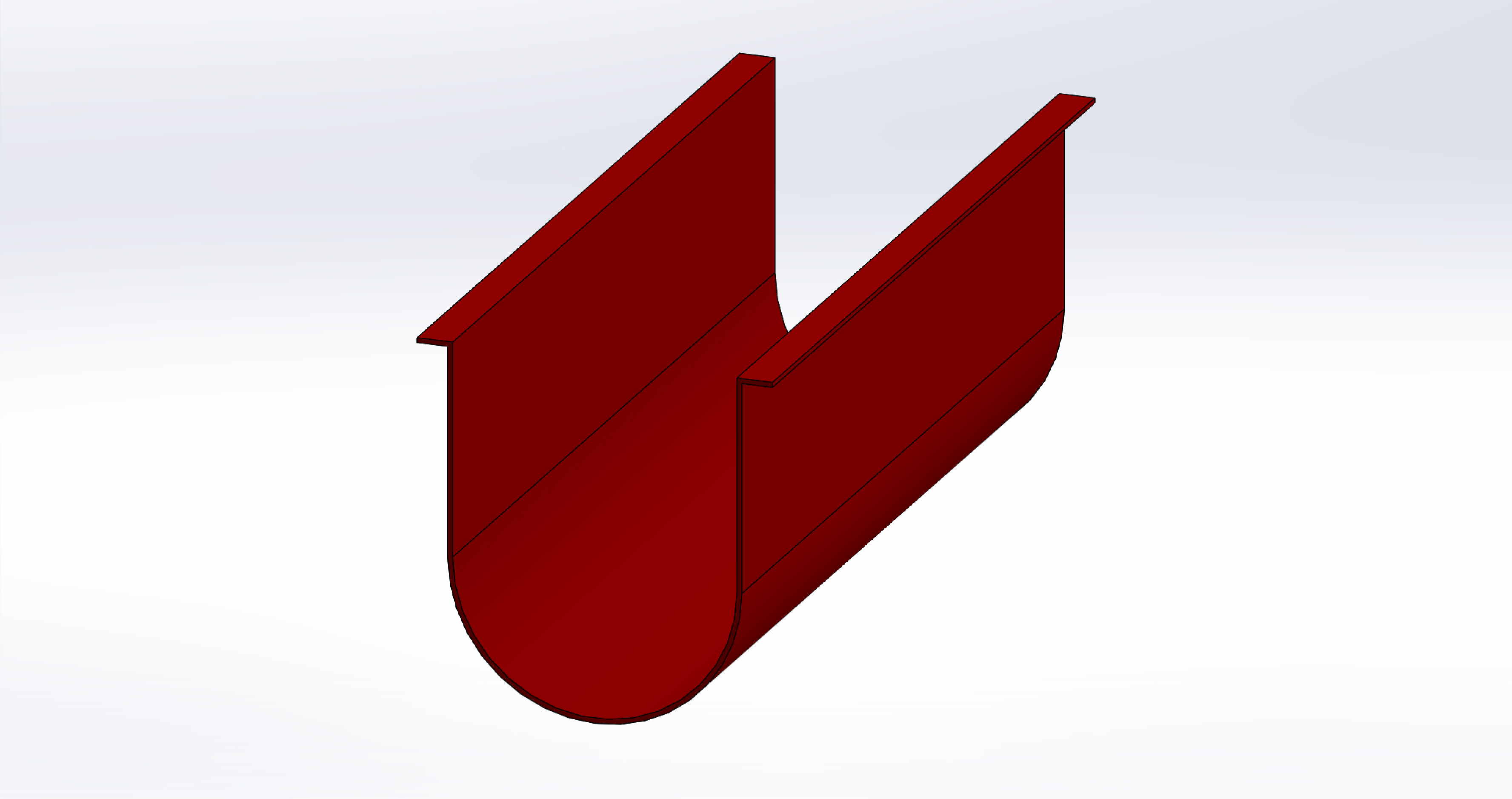

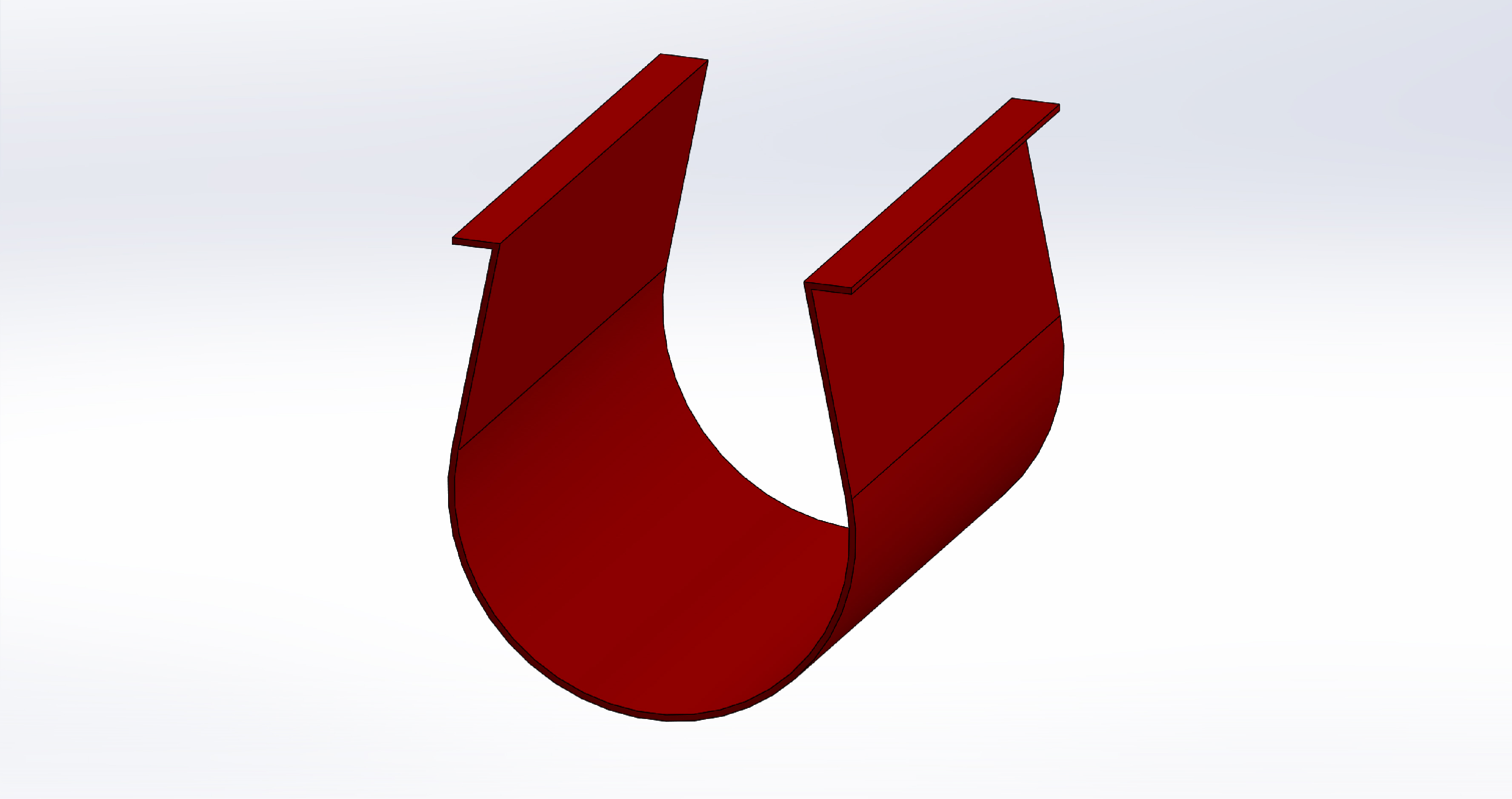

Trough vibrators series MITRO are an inexpensive and effective solution with rectangular work bowl. MITRO trough vibrators are characterised by a single vibration motor mounted under the work bowl. MITRO trough vibrators are particularly suitable for small to medium-sized workpieces or for workpieces that require powerful deburring. The work bowl is made of sheet steel with a polyurethane lining. The vibration motor is equipped with adjustable unbalance weights.

Frame sizes

-

Gross volume:

25 – 320 litres

-

Usable volume::

20 – 250 litres

-

Drive capacities:

0,55 – 2,2 KW*

-

Speed:

1.500 R/min

-

Connector:

400 V / 50 Hz; CEE-Connector*

-

* Depending on the machine size and customer application

Equipment

-

PU-lining

Control types

-

- Control with push-button and digital timer as well as operating hours counter

-

- Control with touch panel and MINI-PLC

-

- PLC control Siemens S7 - customer-specific

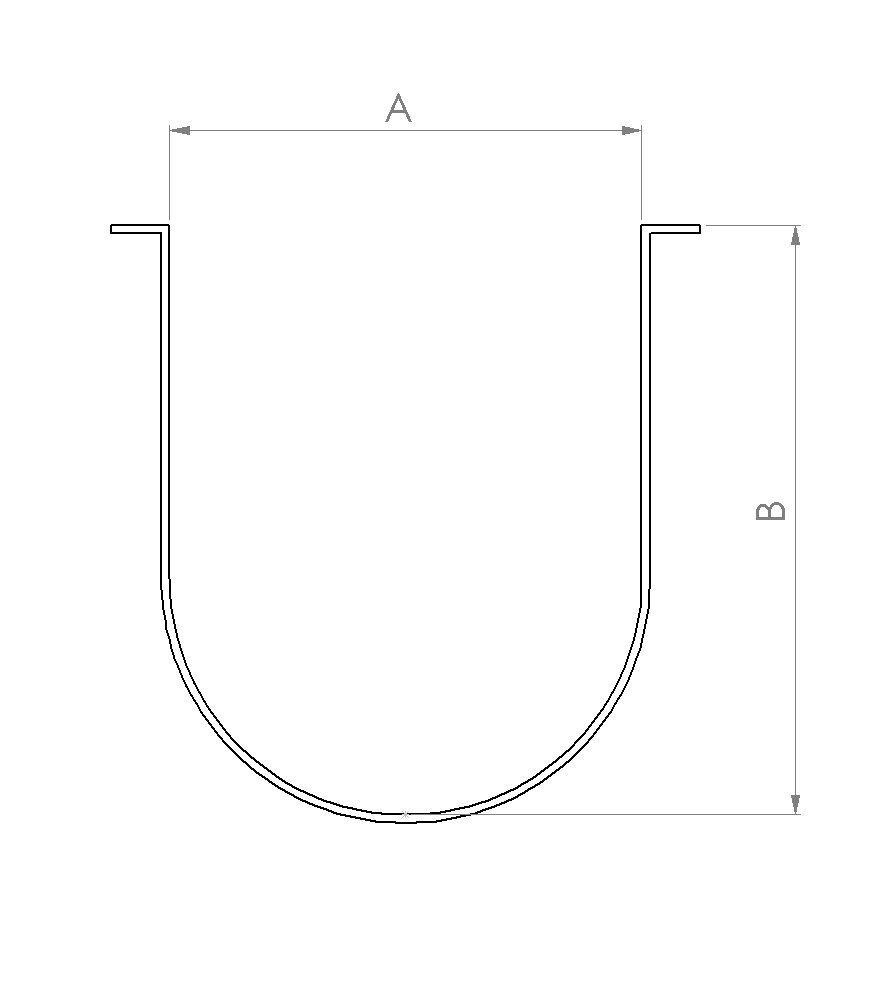

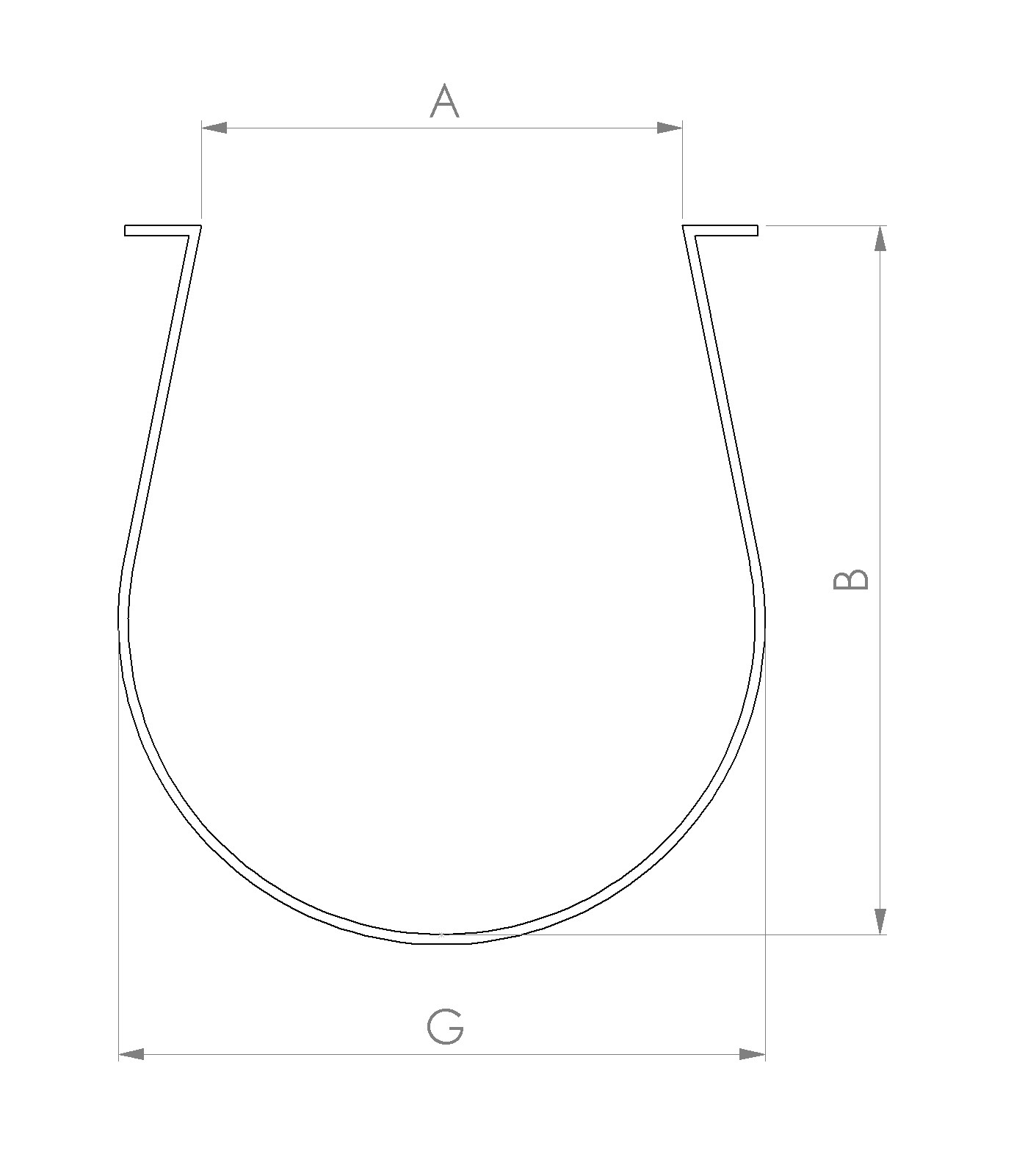

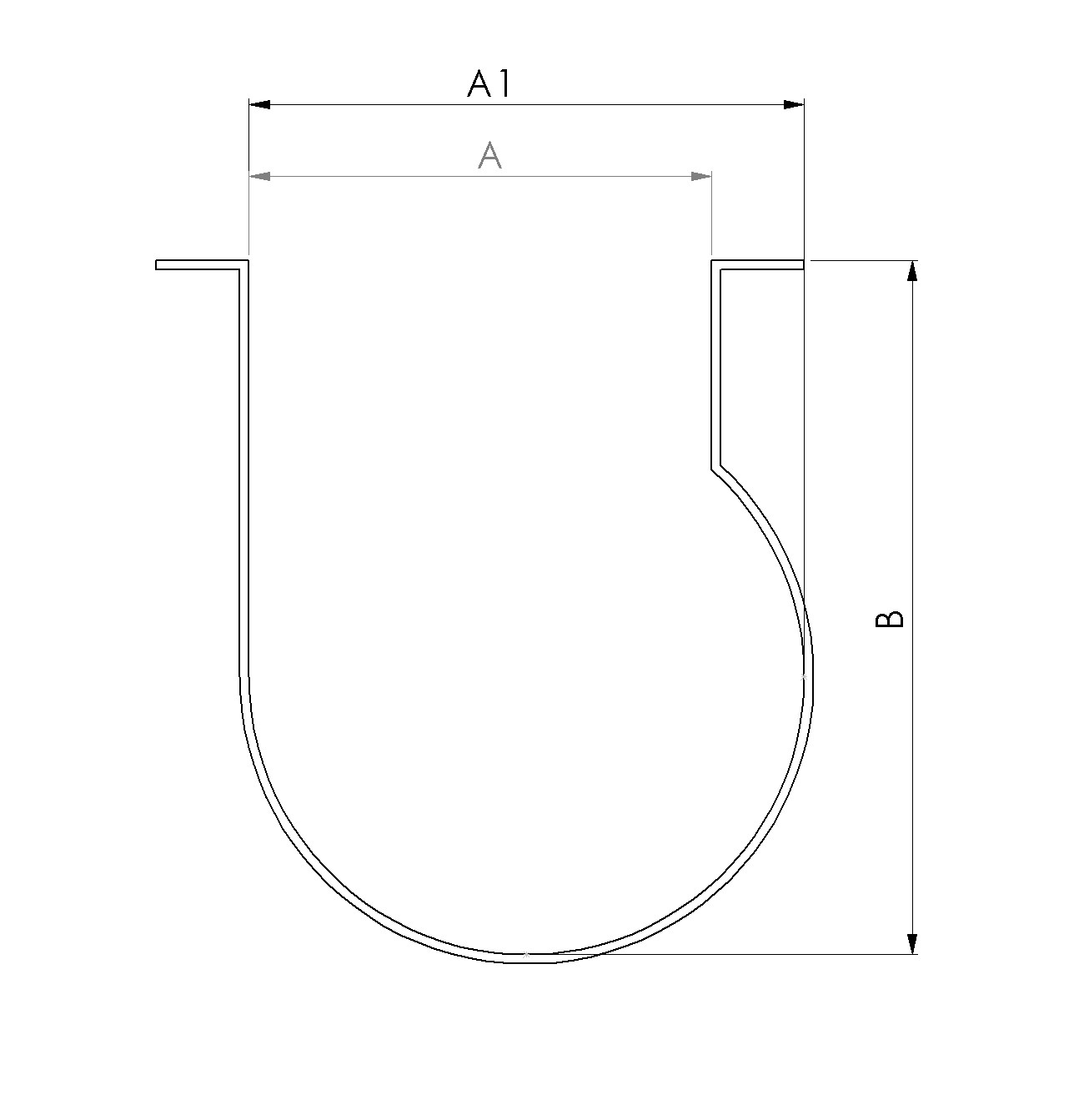

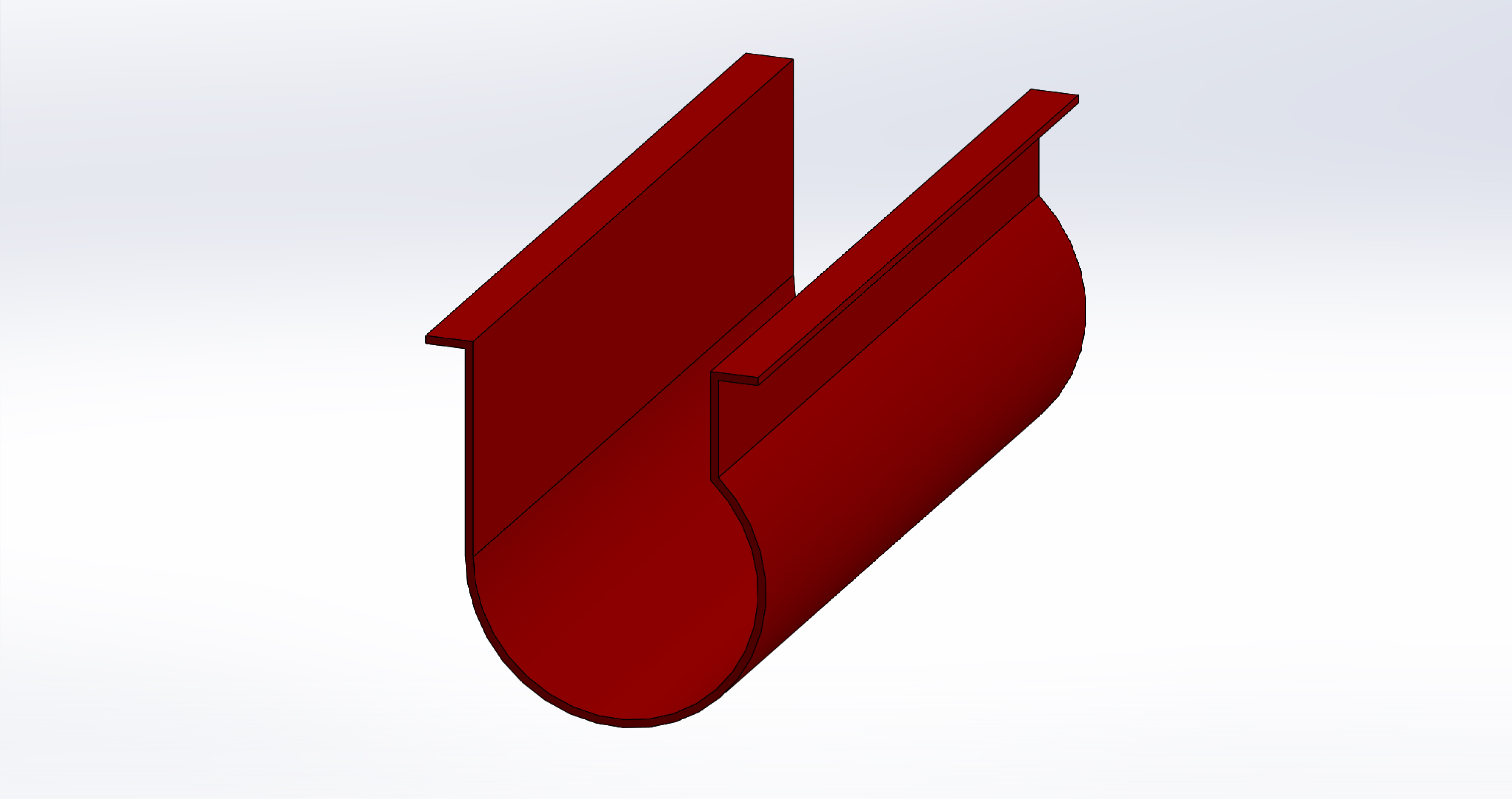

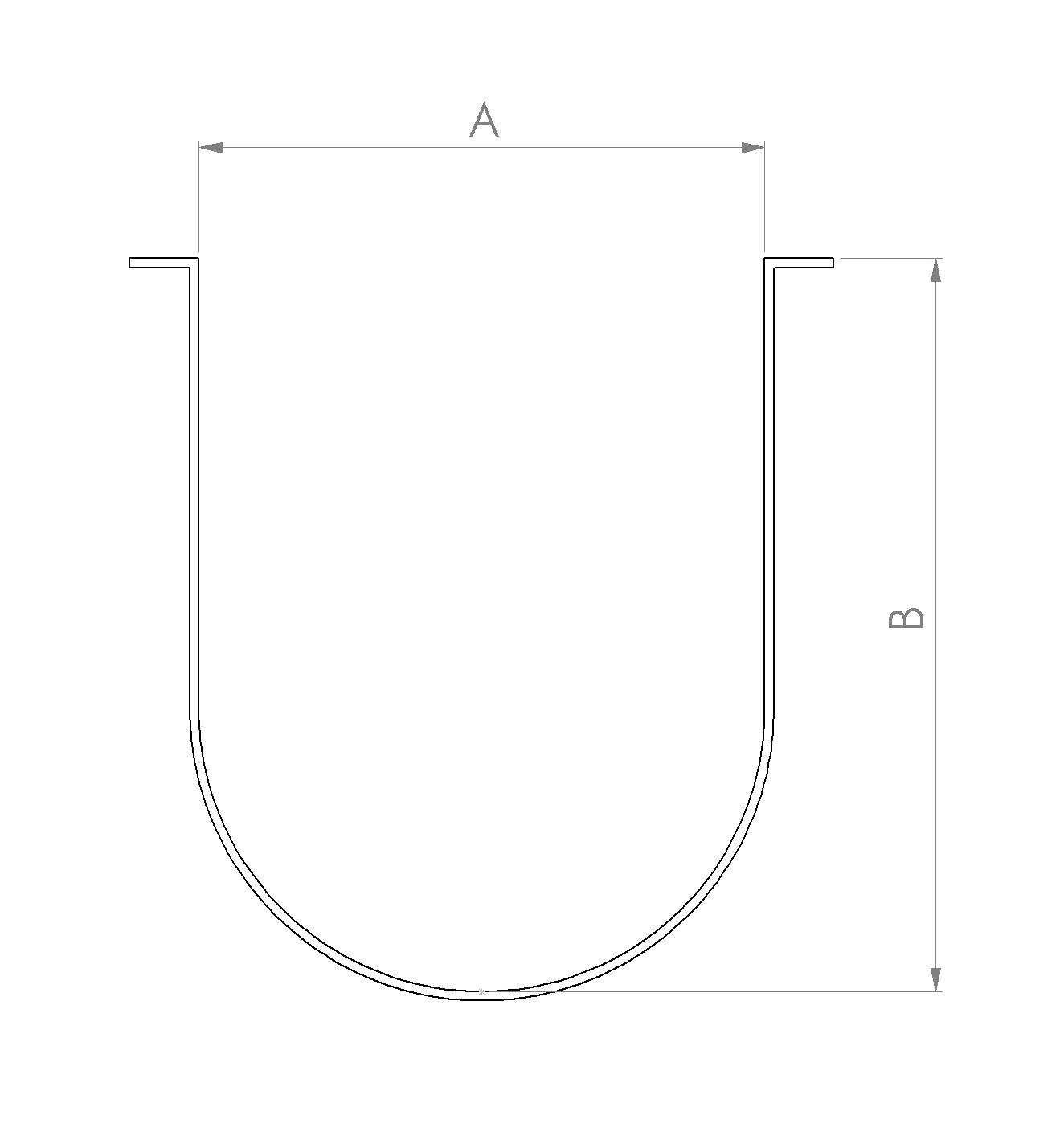

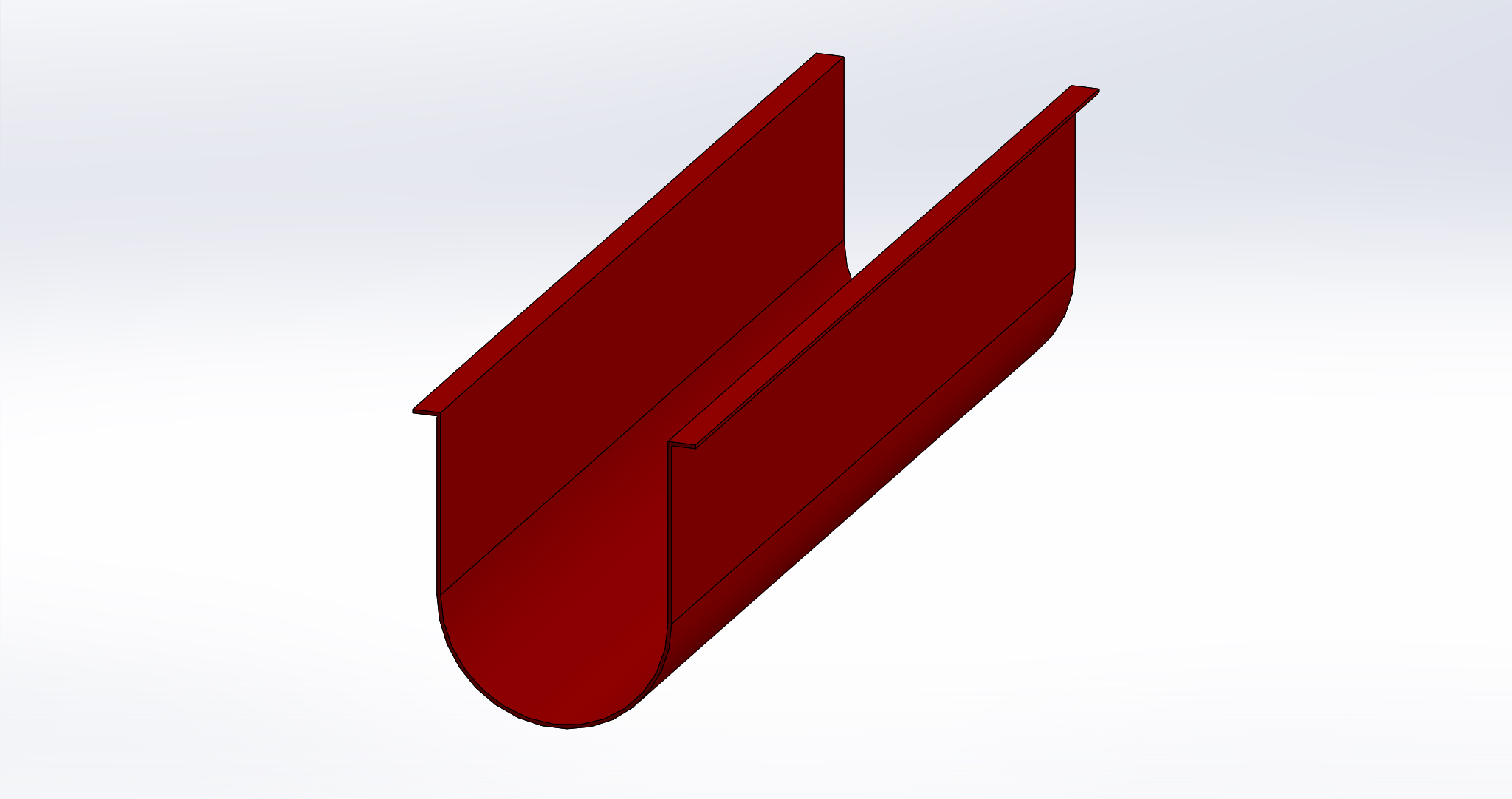

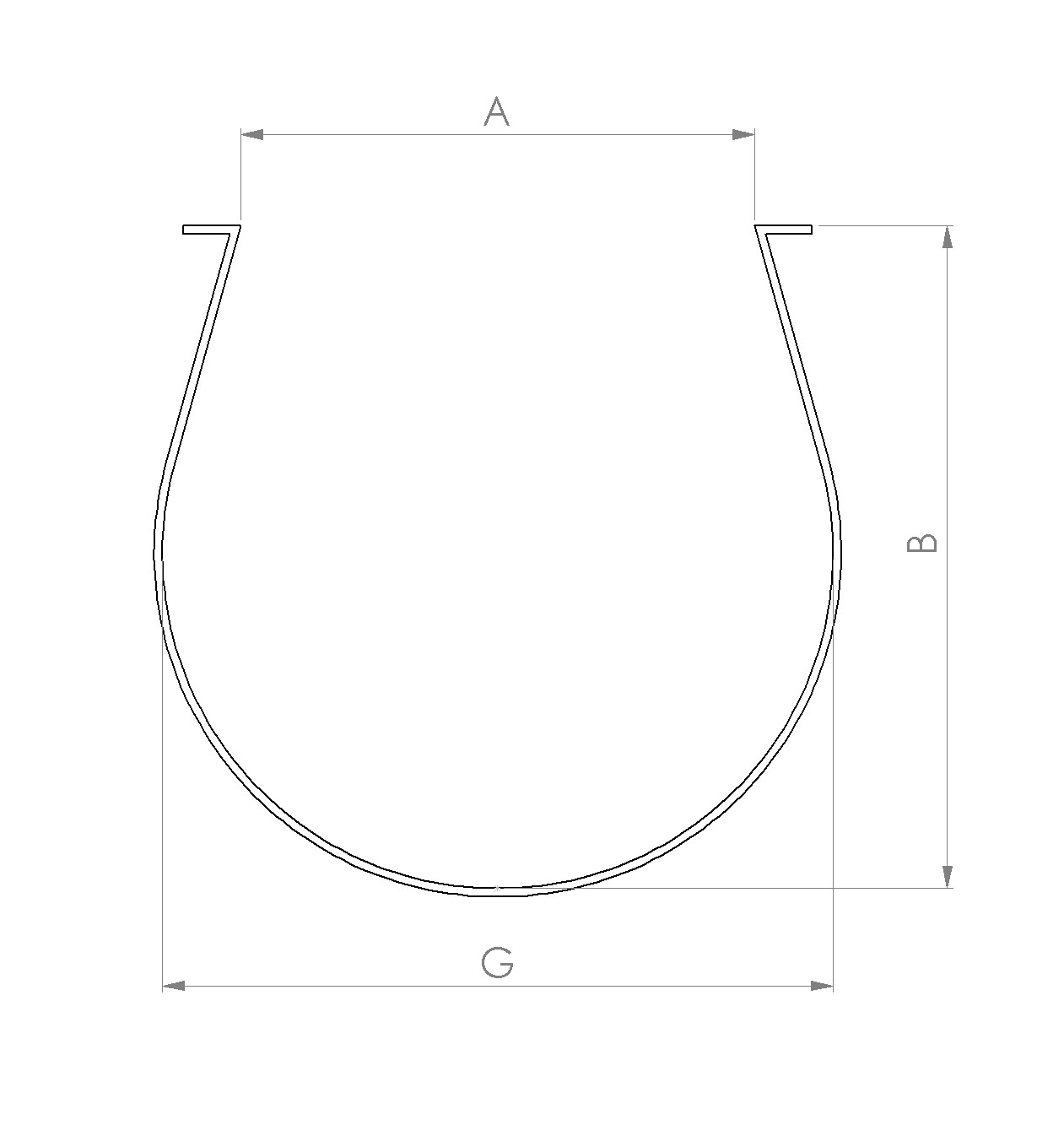

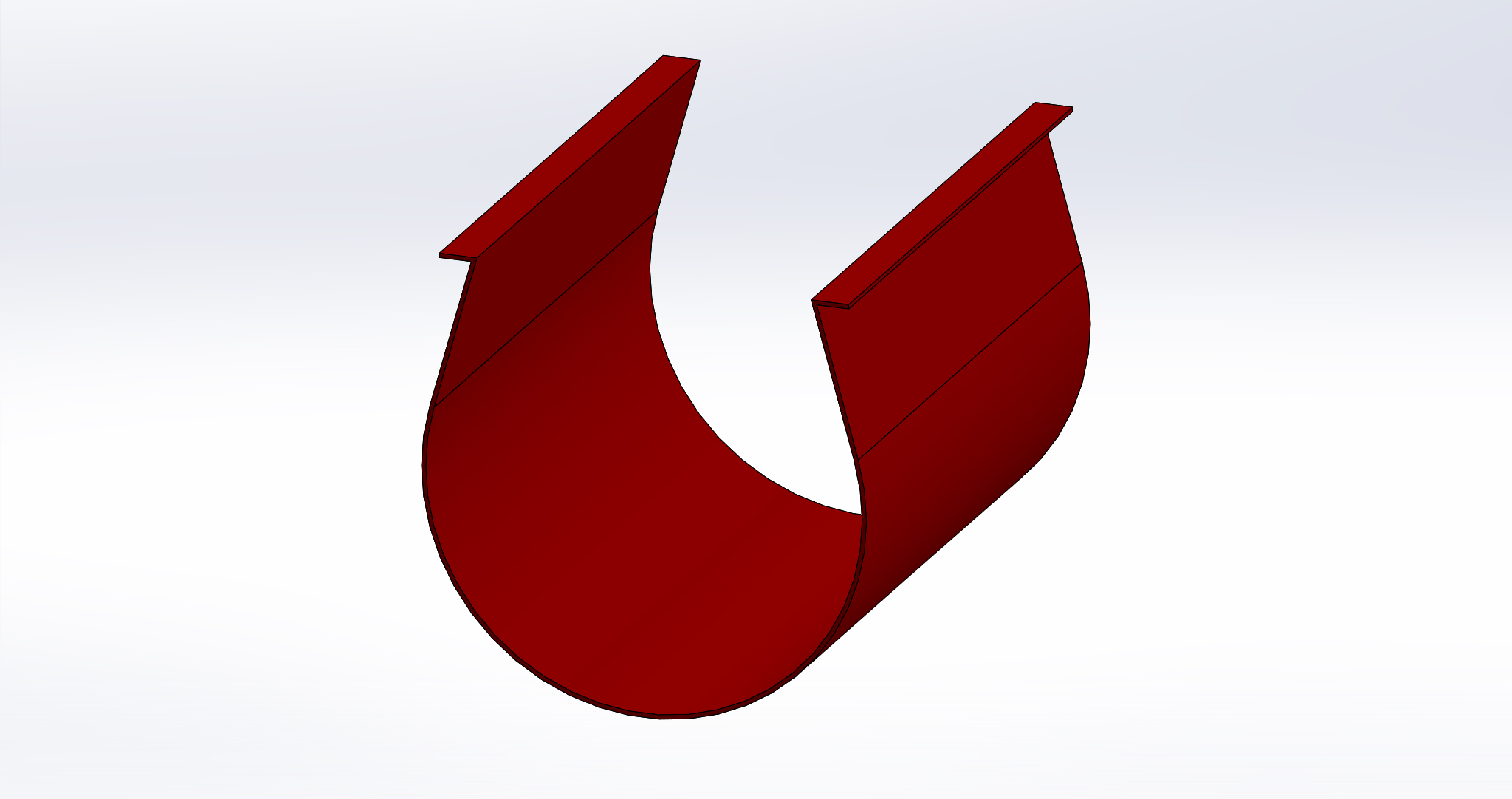

Behälterquerschnitte

Options

-

Separation bulkheads that can be fixed in different positions

-

Frequency converter for weight speed control

-

Soundproof cabin with manual/automatic opening

-

Workpiece carrier

-

Lifting / lowering device pneumatic / hydraulic for workpieces

MITRO-XL

MITRO-XL series

Trough vibrators series MITRO-XL are an inexpensive and effective solution with a rectangular work bowl. MITRO-XL trough vibrators are characterised by a single vibration motor mounted under the work bowl. MITRO-XL trough vibrators are particularly suitable for bulky workpieces or for workpieces that require powerful deburring. The work bowl is made of sheet steel with a polyurethane lining. The vibration motor is equipped with adjustable unbalance weights.

Frame sizes

-

Gross volume:

450 - 1.400 litres

-

Usable volume::

340 - 1.240 litres

-

Drive capacities:

3 - 11 KW*

-

Speed:

1.500 R/min

-

Connector:

400 V / 50 Hz; CEE-Connector*

-

* Depending on the machine size and customer application

Equipment

-

PU-lining

Control types

-

- Control with push-button and digital timer as well as operating hours counter

-

- Control with touch panel and MINI-PLC

-

- PLC control Siemens S7 - customer-specific

Container cross-sections

Options

-

Separation bulkheads that can be fixed in different positions

-

Frequency converter for weight speed control

-

Soundproof cabin with manual/automatic opening

-

Workpiece carrier

-

Lifting / lowering device pneumatic / hydraulic for workpieces